- Products

- Catalogs

- News & Trends

- Exhibitions

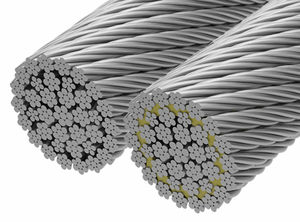

Tensile structure steel cable FLC full locked

Add to favorites

Compare this product

Characteristics

- Applications

- for tensile structures

- Type

- full locked

Description

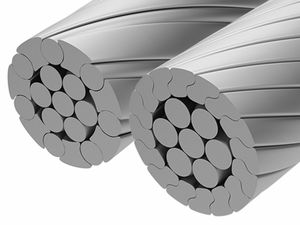

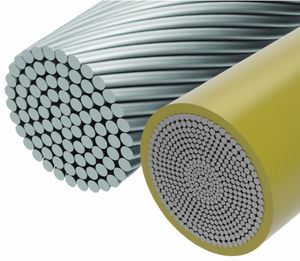

Full Locked Coil strands have a high metallic cross section - this guarantees a higher breaking load and elastic axial stiffness with a smaller/reduced diameter. The outer "Z"-shaped layers give the rope a smoother profile, which allows for better clamping. The locked external surface, the internal compound Tensofill and the zinc–aluminium alloy coating (Zn95Al5) of each external wire allow for a high corrosion protection - that can be further improved with special waxes and extruded or co-extruded HDPE sheathing with wide set of colors and finishings. Redaelli has developed an advanced software which, in addition to the company’s total control of the manufacturing process, allows to customize the locked coil ropes to customer’s requirements. Including custom shaped wires for aerodynamic purposes, low torque cables or other special designs. Full Locked Coil strands are sutable for metal or resin socketing.

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.