- Building & Construction

- Construction site equipment

- Disposable formwork

- DALIFORM GROUP srl

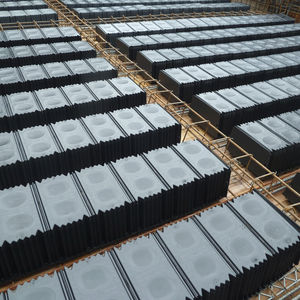

Disposable formwork U-BOOT® BETONlightweightpolypropylenefor slab

Add to favorites

Compare this product

Characteristics

- Type

- lightweight, disposable

- Material

- polypropylene

- Applications

- for floor, for slab

- Other characteristics

- bi-directional, recycled

Description

U-BOOT BETON® IS A RECYCLED POLYPROPYLENE FORMWORK THAT WAS DESIGNED TO CREATE LIGHTENED SLABS AND RAFTS.

The use of U-Boot Beton® formwork makes it possible to create mushroom pillars, with the possibility to have the mushroom in the thickness of the slab.

Thanks to the conic elevator foot, immerging the U-Boot Beton® formworks in the concrete casting will create a gridwork of mutually perpendicular beams closed from the bottom and the top by a flat plate that is created with a single casting; this results in considerable reduction in the use of concrete and steel.

U-Boot Beton® is used to create slabs with large span or that are able to support large loads without beams.

Light and quick and easy to position, thanks to their modularity the designer can vary the geometric parameters as needed to adapt to all situations with great architectural freedom.

1. INCREASED NUMBER OF FLOORS

Possibility to gain floors at the same building height (towers) and building volume.

2. LACK OF RISING BEAMS

Flat soffit for greater flexibility when installing systems.

3. REDUCED SLAB THICKNESS

Thinner slabs but with equal loads and clearances, or bigger clearances with an equal thickness.

4. LARGE SPAN AND GREAT ARCHITECTURAL FREEDOM

Larger spaces. Less architectural restrictions. Freedom of future reconversion of the environments from an architectural-functional point of view.

5. FLEXIBILITY IN THE REALIZATION OF OPENINGS AFTER THE EXECUTION OF THE SLAB

6. REDUCTION IN THE NUMBER OF PILLARS

Facilitated use reallocation. Wider bays.

7. OPTIMISATION OF THE SECTION OF PILLARS

8. IMPROVED ACOUSTIC BEHAVIOUR

Less acoustic transmittance.

VIDEO

Catalogs

Exhibitions

Meet this supplier at the following exhibition(s):

Related Searches

- Daliform formwork

- Daliform modular formwork

- Wall formwork

- Frame formwork

- Daliform plastic formwork

- Daliform adjustable formwork

- Daliform floor formwork

- Custom formwork

- Daliform disposable formwork

- Lightweight formwork

- Slab formwork element

- Foundation formwork

- Recycled formwork

- Cardboard formwork

- Polypropylene formwork

- Basin formwork

- Crawl space formwork

- Concrete formwork

- Expanded polystyrene formwork

- Recyclable formwork

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.