- Building & Construction >

- Construction site equipment >

- Lightweight formwork

Lightweight formwork

Lightweight formwork is a crucial component in the construction industry, designed to shape concrete structures efficiently while being easy to handle and install. As a professional browsing through a variety of lightweight formwork options, it’s important to find a product and manufacturer that align perfectly with your project requirements and budget. This guide will help you navigate the pricing landscape of lightweight formwork and provide tips on requesting quotes effectively.

When considering lightweight formwork, several factors influence the price, including:

- Material Type: The materials used in formwork, such as aluminum, plastic, or composite, significantly impact the cost. Aluminum is more expensive but offers durability and reusability.

- System Design: Modular systems with advanced engineering can be more costly due to their flexibility and ease of use.

- Brand and Manufacturer: Established brands with a reputation for quality may charge premium prices.

- Project Scale: Larger projects may benefit from bulk pricing, whereas smaller projects might incur higher per-unit costs.

Price ranges for lightweight formwork can vary widely. Entry-level products might start at around $50 per square meter, suitable for smaller or less demanding projects. Mid-range options, offering a balance of quality and cost, typically range from $80 to $150 per square meter. High-end formwork systems, offering superior durability and efficiency, can exceed $200 per square meter.

The difference between entry-level and high-end products often lies in the materials used, the complexity of the system, and the brand reputation. High-end products generally offer better longevity, adaptability, and ease of installation, which can result in long-term cost savings.

To negotiate the best quote, consider:

- Volume Discounts: Inquire about discounts for larger orders or long-term contracts.

- Customization Options: Discuss any specific needs or customizations that might affect pricing.

- Flexible Payment Terms: Negotiate payment terms that can help manage cash flow effectively.

Beyond the initial product price, factor in additional costs such as shipping, installation, and maintenance to get a complete picture of the total investment.

In conclusion, understanding the factors that influence lightweight formwork pricing will empower you to make informed decisions. Utilize our marketplace’s resources and tools to compare products, get detailed information, and request quotes from multiple manufacturers to ensure you secure the best deals for your projects.

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

... horizontally due to internal tie-points • A floor height of up to 3 m can be formed with just one extension • Keybolts as lightweight, friction-locked and cost-effective connecting pieces • Easy attachment of accessories ...

... cross profiles • Compatible with LOGO.3 with steel frame • Multi-purpose panel for corners, columns, stop ends Light-weight formwork for construction sites without cranes and fully compatible to ...

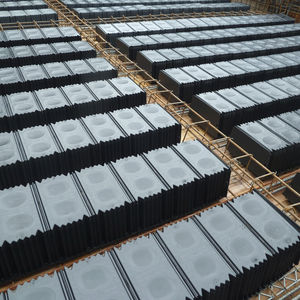

U-BOOT BETON® IS A RECYCLED POLYPROPYLENE FORMWORK THAT WAS DESIGNED TO CREATE LIGHTENED SLABS AND RAFTS. The use of U-Boot Beton® formwork makes it possible to create mushroom pillars, with the possibility ...

DALIFORM GROUP srl

... between the beams are filled by Atlantis System formworks. Muro formwork in coherence with its purpose, which is quick and easy work in the construction site, is characterised by simple, lightweight ...

DALIFORM GROUP srl

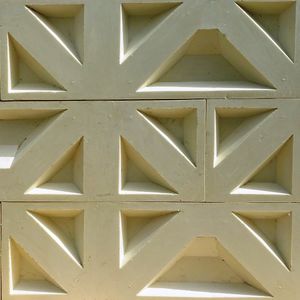

... reduced use of concrete and steel as well as considerable advantages in terms of fire risk in comparison to formworks in expanded polystyrene. Light and stackable, it is easy to handle during positioning, ...

DALIFORM GROUP srl

AluFix is MEVA's lightweight hand-set formwork. The modular aluminium system impresses by its optimum height increments for efficient shuttering without vertical extension. Product characteristics Flexibility Panel ...

... , used for the realization of bidirectional lightened floors. It replaces the lightening in bricks and polystyrene. The formworks are availables singles or doubles, the four versions are all modulars to satisfy the different ...

... latest product of Farina Formworks: a light steel frame formwork, handset and therefore avoiding the use of crane and maintaining a high flexibility, thanks to its modularity. If you ...

Farina Formworks

ARCOFORM formwork in polystyrene foam is used to create concrete arches directly at the building yard. Lightweight and ready for use, ARCOFORM enables you to reduce setting up and installation costs ...

Geotub Panel is modular reusable plastic formwork for the creation of rectangular and square columns, that can be reused more than 100 times. It is better than wooden or metal options, since it is lightweight, ...

GEOPLAST

... recycling of aluminium beams. The lowest weight per m² formwork on the market Made of aluminium, the frames and beams contribute to making the TopDalle portable formwork system so lightweight. Less ...

ALPHI SAS

The best material on the market with regard to thermal and acoustic insulation. The heat required for a construction is < 5W/m2 if the inside – outside temperature difference is of 40°C. There are no thermal bridges: no mould; no ...

Handi is a lightweight framed formwork system, which has been specially designed for quick and cost-saving construction. Thanks to its lightweight panels the forming process is effectively ...

Variant Factory Ltd

It is a modular system of formwork in aluminum for the execution of monolithic or lightened concrete slabs cast in place. SLABFORM is a fully industrialized formwork system that does not require specialized ...

Pilosio

Twin wall fluted polypropylene board for ground beam & shuttering Beam formwork Our polypropylene sheets are both rigid and lightweight, making them an ideal material for concrete ...

Your suggestions for improvement:

Subscribe to our newsletter

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how ArchiExpo processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining