- Building & Construction

- Construction site equipment

- Modular formwork

- Variant Factory Ltd

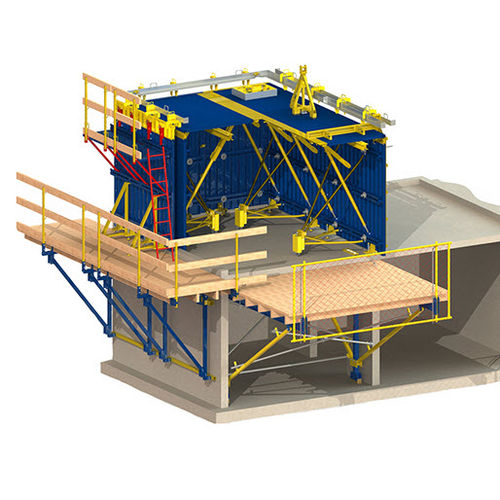

Tunnel formwork modularsteel

Add to favorites

Compare this product

Characteristics

- Type

- modular

- Material

- steel

- Applications

- for tunnel

Description

Tunnel Formwork is a system which allows simultaneous casting of walls and slab in one pouring cycle. Half tunnels can be stripped and moved out to the next phase/level the nest day after the pouring. Having faster workflow and being easier to operate with, compared to conventional systems, use of the system can save up to 50% of formwork budget. The system enables you to have smooth concrete surface, dimensional accuracy and eliminates finishing works like plastering. Moreover the system creates good load-bearing concrete structure, which can be applicable for projects in seismic areas.

Load-bearing capacity:

High load-bearing capacity.

Cost-effective:

Rapid pace of work and cutting of re-assembly cost due to the repositioning of complete units;

High quality of concrete surface minimizes finishing work;

High number of use cycles (up to 500) means lower follow-up expenses.

Easy handling and planning:

Small number of different parts is used;

Time and cost-effective owing to use of preassembled half tunnels;

The formwork can be plumbed and aligned very quickly and accurately in all directions.

Safe use:

Safe working conditions provided by systems safe equipment.

Catalogs

No catalogs are available for this product.

See all of Variant Factory Ltd‘s catalogsRelated Searches

- Formwork element

- Modular formwork element

- Metal formwork element

- Wall formwork

- Column formwork

- Frame formwork

- Sheet steel formwork

- Adjustable formwork element

- Wood formwork

- Custom formwork

- Work platform

- Circular formwork

- Lightweight formwork

- Plywood formwork

- Large-area formwork

- Construction platform

- Slab formwork element

- Foundation formwork

- Outdoor platform

- Shoring tower

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.