Decorative metal sheet GATES HALL AT CORNELLperforatedstainless steelgalvanized steel

Add to favorites

Compare this product

Characteristics

- Type

- decorative, perforated

- Material

- stainless steel, galvanized steel

- Applications

- for facade cladding

- Options

- with round perforations

Description

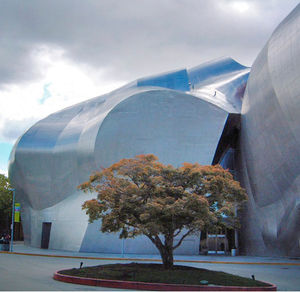

Gates Hall is a new computer science building for students of Cornell in Ithaca, New York. Designed by Morphosis Architects, the building features Zahner custom systems for the soffit, interior entry foyer, and exterior facade. The building, named for Bill & Melinda Gates, is a dedicated building for Cornell University's Computing and Information Science (CIS) program.

The project's facade is designed using generative processes developed by Morphosis. Its unique appearance also serves the building's environment performance, reducing heat gain while providing natural light into the offices and classrooms.

The complex facade appears to be made up of unique parts, but there are several typical forms which are cleverly spaced to give the appearance that each part is unique. This technique of using the negative space to create complex visuals is a hallmark of the architecture firm's genius, and can be seen on other Morphosis projects such as Emerson College LA and Bloomberg Center.

Zahner worked with Morphosis to optimize the frame panel system, reducing it to the fewest number of components. By switching from bulky hollow frames to a combination of angles and plates, Zahner minimized the leading edges and simplified its compound joint conditions, resulting in sharper lines and cleaner forms at a reduced cost.

Field time and layout were reduced immensely by using a three-point attachment scheme and coordinating anchor locations beforehand, which were fabricated into the mullions. There are 450 total framed panels using 90 panel types, fabricated by Zahner for the facade.

Catalogs

No catalogs are available for this product.

See all of A. Zahner‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.